Muchina wepellet mudziyo wekumanikidza biomass pellet mafuta uye pellet feed, pakati peiyo yekumanikidza roller ndicho chikamu chayo chikuru uye chikamu chinotambura. Nekuda kwekuremerwa kwebasa uye nemamiriro ekushanda akaomarara, kunyangwe nemhando yepamusoro, kusakara uye kubvaruka hazvidzivisike. Muchigadziro chekugadzira, kushandiswa kwekumanikidza rollers kwakakwira, saka zvinhu uye nzira yekugadzira yekumanikidza rollers inonyanya kukosha.

Kutadza kuongororwa kweiyo pressure roller yemuchina wepakati

Iyo nzira yekugadzira yekumanikidza roller inosanganisira: kucheka, forging, normalizing (annealing), rough machining, kudzima uye kupisa, semi precision machining, kudzima kwepamusoro, uye kunyatsogadzira machining. Chikwata chehunyanzvi chakaita ongororo yekupfeka kwebiomass pellet mafuta ekugadzira uye kugadzirisa, ichipa hwaro hwekufungidzira hwekusarudzwa kwakanaka kwezvinhu zvema roller uye maitiro ekurapa kupisa. Izvi zvinotevera mhedzisiro yetsvakiridzo uye kurudziro:

Dents uye zvikwambo zvinoonekwa pamusoro peiyo pressure roller yegranulator. Nekuda kwekupfeka kwetsvina yakaoma sejecha nesimbi filings pane yekumanikidza roller, ndeyekupfeka zvisina kujairika. Ivhareji yepamusoro inopfeka inenge 3mm, uye kupfeka kumativi ose akasiyana. Rutivi rwekudyisa rune kupfeka kwakanyanya, nekupfeka kwe4.2mm. Kunyanya nekuda kwekuti mushure mekudya, iyo homogenizer yakanga isina nguva yekugovera zvakaenzana zvinhu uye yakapinda mu extrusion process.

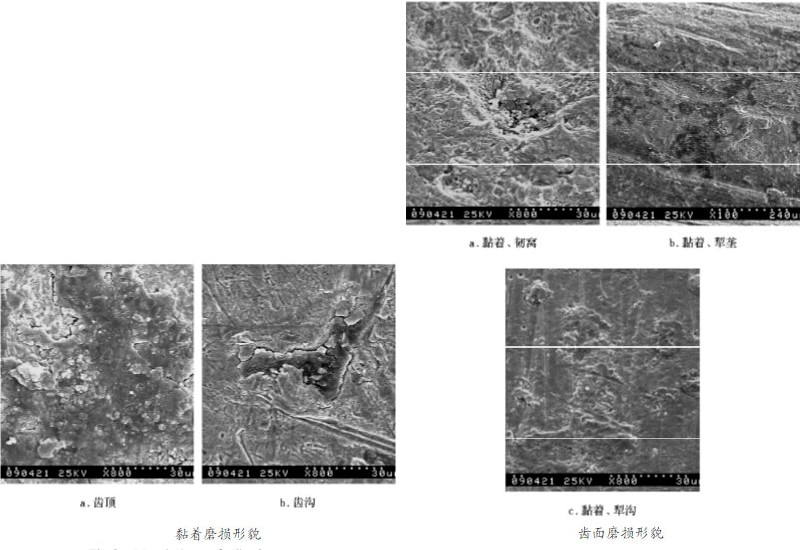

Microscopic kupfeka kutadza kuongororwa kunoratidza kuti nekuda kwekupfeka kweaxial pamusoro peiyo yekumanikidza roller inokonzerwa neyakagadzirwa zvinhu, kushaikwa kwezvinhu zvepasi pane yekumanikidza roller ndicho chikonzero chikuru chekutadza. Iyo mikuru yekupfeka ndeyekunamatira kupfeka uye abrasive kupfeka, ine morphology yakadai semakomba akaoma, magejo egejo, gejo grooves, nezvimwewo, zvichiratidza kuti silicates, jecha particles, iron filings, etc. mune yakasvibira zvinhu zvine kusakara kwakakomba pamusoro peiyo yekumanikidza roller. Nekuda kwekuita kwemhute yemvura uye zvimwe zvinhu, madhaka senge mapatani anoonekwa pamusoro peiyo pressure roller, zvichikonzera kushushikana kuora kutsemuka pamusoro peiyo pressure roller.

Inokurudzirwa kuwedzera nzira yekubvisa tsvina isati yapwanya zvinhu zvakasvibirira kubvisa jecha zvidimbu, masimbi esimbi, uye mamwe matsvina akavhenganiswa mune zvigadzirwa, kuitira kudzivirira kusapfeka kusina kujairika uye kubvarura pane zvinomanikidza rollers. Shandura chimiro kana chinzvimbo chekuisa cheiyo scraper kugovera zvakaenzana zvinhu mukamuri yekumanikidza, kudzivirira kusaenzana kwesimba pane yekumanikidza roller uye kuwedzera kupfeka pamusoro peiyo pressure roller. Nekuda kwekuti iyo yekumanikidza roller inonyanya kutadza nekuda kwekupfeka kwepamusoro, kuitira kuti ivandudze kuomarara kwayo kwepamusoro, kusagadzika kwekusapfeka, uye kusagadzikana kwekuora, zvinhu zvinodzivirira kupfeka uye nzira dzakakodzera dzekurapa kupisa dzinofanirwa kusarudzwa.

Material uye maitiro ekurapa kwekumanikidza rollers

Iko kuumbwa kwezvinhu uye maitiro eiyo pressure roller ndizvo zvinodikanwa zvekuona kusakara kwayo. Izvo zvinowanzo shandiswa roller zvinhu zvinosanganisira C50, 20CrMnTi, uye GCr15. Maitiro ekugadzira anoshandisa CNC maturusi emuchina, uye iyo roller pamusoro inogona kugadzirwa nemazino akatwasuka, mazino oblique, mhando dzekuchera, nezvimwe zvinoenderana nezvinodiwa. Carburization quenching kana yakakwirira-frequency quenching kupisa kurapwa inoshandiswa kuderedza roller deformation. Mushure mekurapa kwekupisa, kunyatsogadzira machining kunoitwa zvakare kuti ive nechokwadi chekutarisa kwemukati nekunze madenderedzwa, izvo zvinogona kurebesa hupenyu hwebasa re roller.

Kukosha kwekurapa kwekupisa kune kudzvinyirira rollers

Kuitwa kwekumanikidza roller kunofanirwa kusangana nezvinodiwa zvesimba rakakura, kuomarara kwepamusoro (kupfeka kusagadzikana), uye kusimba kwepamusoro, pamwe nekunaka machinability (kusanganisira kupenya kwakanaka) uye kushomeka kwemarara. Kupisa kurapwa kwepressure rollers inzira yakakosha inotarirwa kusunungura kugona kwezvinhu uye kuvandudza mashandiro avo. Iine simba rakananga pakugadzirwa kwechokwadi, simba, hupenyu hwebasa, uye mari yekugadzira.

Nezvezvinhu zvimwechetezvo, zviwanikwa zvakapfuura nekupisa zvine simba rakawanda, kuomarara, uye kusimba kana zvichienzaniswa nemidziyo isina kurapwa zvakanyanya. Kana isina kudzimwa, hupenyu hwebasa rekumanikidza roller huchava hupfupi.

Kana iwe uchida kusiyanisa pakati pezvikamu zvinopisa uye zvisina kupisa-zvinopisa zvakamboitwa machining, hazvibviri kuzvisiyanisa chete nekuoma uye kupisa kurapwa oxidation ruvara. Kana iwe usingade kucheka uye kuyedza, unogona kuedza kuvasiyanisa nekutapa ruzha. Iyo metallographic chimiro uye yemukati friction yekukanda uye kudzimwa uye kushatirwa workpieces zvakasiyana, uye zvinogona kusiyaniswa nekurova zvinyoro.

Kuoma kwekurapa kwekupisa kunotarirwa nezvinhu zvakati wandei, zvinosanganisira giredhi rezvinhu, saizi, huremu hwebasa, chimiro uye chimiro, uye inotevera nzira dzekugadzirisa. Semuenzaniso, kana uchishandisa chitubu waya kuita zvidimbu zvakakura, nekuda kwekukora chaiko kweiyo workpiece, bhuku racho rinotaura kuti kuomarara kwekupisa kunogona kusvika 58-60HRC, iyo isingakwanisi kuwanikwa pamwe chete neayo workpieces. Mukuwedzera, zviratidzo zvekuoma zvisina musoro, zvakadai sekunyanya kuoma, zvinogona kuguma nekurasikirwa kwekuoma kwebasa rekushanda uye kukonzera kuputika panguva yekushandiswa.

Kurapa kwekupisa hakufanirwe kungovimbisa kukosha kwekuomarara kwakakodzera, asiwo kutarisisa kusarudzwa kwayo kwemaitiro uye kutonga kwemaitiro. Overheated quenching uye kupisa kunogona kuzadzisa kuoma kunodiwa; Saizvozvo, pasi pekudziya panguva yekudzima, kugadzirisa tembiricha yekudziya kunogonawo kusangana neinodiwa kuomarara renji.

Iyo Baoke pressure roller yakagadzirwa nesimbi yemhando yepamusoro C50, ichivimbisa kuoma uye kupfeka kuramba kweiyo particle machine pressure roller kubva kunobva. Yakasanganiswa neyakakura-tembiricha yekudzima tekinoroji yekurapa kupisa, inowedzera zvakanyanya hupenyu hwayo hwesevhisi.

Nguva yekutumira: Jun-17-2024